Anugraha valve castings Improves tool design time using PTC Creo

Total Views |

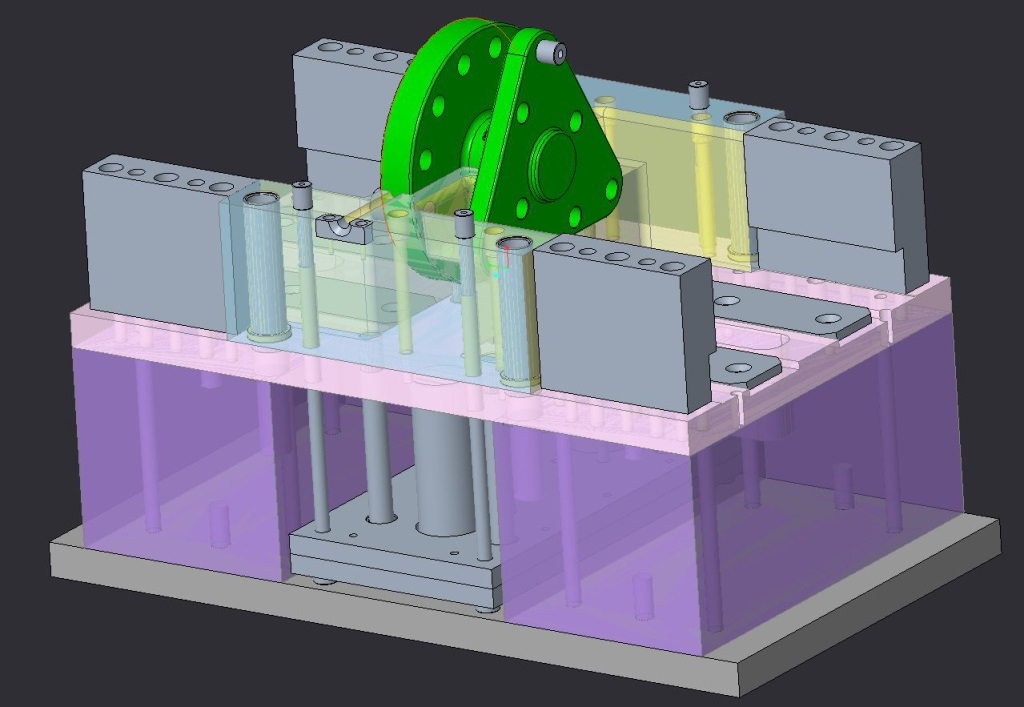

How Anugraha Valve Castings is using PTC Creo Tooling Design solutions for the manufacturing of Investment die Castings

Decrease design time

Initiative: To decreasing design time by optimizing tool concept design

Results: With PTC Creo Tool Design and Intelligent smart Library capabilities, our Tool designs are made faster and able to maintain the standardization in the tool design process

Ability to handle complex designs and reduce errors

Initiative: Ability to handle complex designs and reduce errors

Results:Due to a single integrated platform, design changes are seamlessly reflected in Tooling

Customer satisfaction

Initiative: To ensure customer satisfaction by enhancing product value with continuous upgrade of techniques and processes

Results: High product quality & robustness leads to more Customer satisfaction and rely on our products

Handling complex designs

Initiative: Maintain a single platform for Design & Tooling activity

Results: With PTC Creo Tool Design Option, Complex parting surfaces are made easier and surface errors are reduced to a greater extent.

In order to improve time to market and provide high Quality of Investment die castings, Anugraha wants to implement Integrated tooling solutions and new technologies “With help of PTC Creo Tooling Solutions, we could able to maintain consistent product quality, delivery, cost and thereby improved our Customer satisfaction by Globally….” – Jayekumar Asst Manager-Design