3D Coolant CFD

31 Jul 2023 12:41:42

What Can Moldex3D Do?

Improve cooling efficiency to enhance part qualityPredict required cooling flow rateReduce cycle time and costsCalculate flow properties, such as temperature, pressure, and velocityPredict potential welding line, sink mark, warpage, pressure loss, etc.Estimate transient mold temperatureSupport parallel processing to speed up the simulation process

Applicable Industries

Electronics, Mechanical, Consumer Product

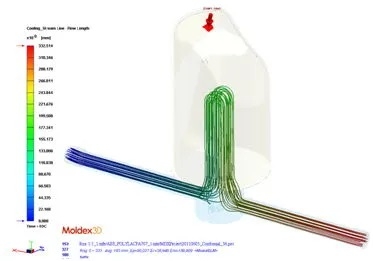

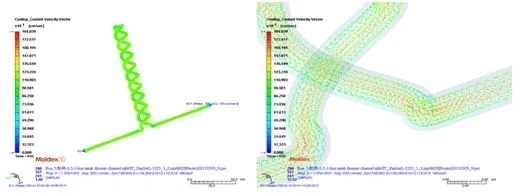

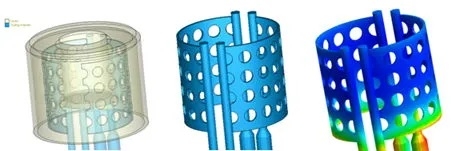

Conformal Cooling Design Validation

How to design an efficient cooling system is critical for part quality and cycle time in the injection moldingprocess. Among various cooling solutions, conformal cooling has gained importance due to its proven success in cost and cooling time reduction. Moldex3D assists users in evaluating the effectiveness of cooling layout design and validating potential molding problems.

Explore Moldex3D’s Capabilities

- CAD models in STL format can be imported and defined as cooling channels or heating rods in Designer.

- Baffle and bubbler designs can be simulated and analyzed.