C&S Electric reduces development time by 20-30% using PTC CREO Mechanism Dynamics

Total Views |

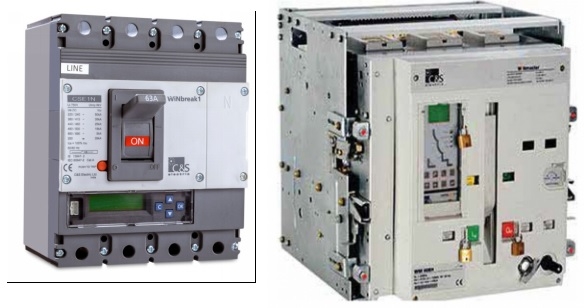

How C&S Electric is using 3D modeling, Assembly design & Mechanism Dynamics for meeting excellence in Circuit Breaker Design & Development

Initiative:Reduce new product development cost of physical prototypes

Result:With fewer changes in product design, prototyping cost including re-works and scrap has greatly reduced

Reduction in Development Time

Initiative: Detect clearance and interference problems early in the design phase

Result:Creo mechanism module has helped us check assembly clearance and interference early in the design phase saving product validation time by 30%

Research and Development

Initiative: Simulate real-world forces in Circuit Breaker to analyze its behavior in working conditions

Result: Mechanism Dynamics lets us simulate working condition with effective utlization of springs, forces, cams, force motors etc. to analyze product behavior in virtual environment

Easy to Communicate

Initiative: Share product behavior with cross-functional teams for clear communication of product performance

Result:Visualization has made the decision making much faster. Creo mechanism motion animations and performance graphs help us share critical communication with other teams

Customer Quote

PTC Creo Parametric helps us in developing new products as well as cost optimization of old products. We have reduced up to 30% time for developing new products ”

– Sudhakar Sapuram (AVP – R&D)