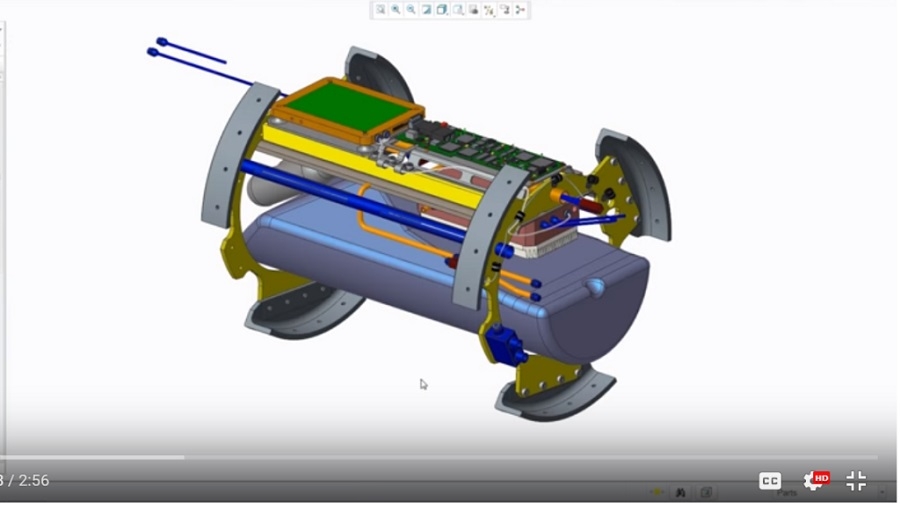

Creo Piping and Cabling Extension

Total Views |

Creo PCX automates routing as you design—regardless of the industry you work in. By making fluid and electrical design an integral part of the detailed design process, Creo PCX minimizes rework, improves efficiency, and makes development faster.

Capabilities:

- Capture and document schematic information and manufacturing documentation.

- Minimize errors and reduce time-consuming tasks by automating the capture of all relevant system information, such as the schematic design, virtual prototype, or manufacturing documentation.

- Fully automate your routing so you can quickly determine the optimum path for manufacturing, cost, and serviceability.

- Ensure design rules and schematic logic rules are enforced through specification-driven design.

- Increase design speed through the reuse of standard symbols, connectors, and fittings contained in a customizable library.

- Reduce costs and design time by eliminating the need for physical prototypes, made possible through virtual interference checking and automated manufacturability verification.

- Enable cost-effective manufacturing through accurate documentation, such as isometric drawings, bend tables, and BOMs