Analyze and Document Geometric Tolerances Directly on 3D CAD Models

02 Aug 2023 11:19:39

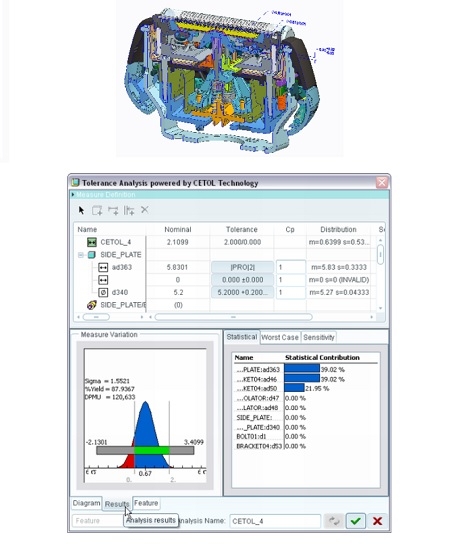

With Creo Tolerance Analysis Extension (TAE), an extension to Creo Parametric, we can evaluate the impact of tolerances and dimension on product designs before the product reaches either prototyping or manufacturing.

Creo TAE provides two analysis tools: worst-case analysis and statistical analysis. Worst-case analysis, often used for critical components, considers what happens when each of the components in the stack-up reaches the maximum acceptable measurement. In statistical analysis each component’s variation is modeled as a statistical distribution. These distributions then are added together to predict the distribution of the assembly measurement. Using these tools, designers can produce products that meet customer requirements within acceptable margins. The result: shorter product development cycles, lower product cost, and higher product quality.

Creo Tolerance Analysis Extension (TAE) Features and Benefits

Evaluate the impact of tolerances on the manufacture of designs.

Enable concurrent engineering to ensure designs meet manufacturing requirements.

Six Sigma design methodologies to ensure design quality.

Streamline design processes, improve productivity, and reduce time-to-market.

Placeholder components enable simulation of dimension properties that are not accounted for in the CAD model.

Automatically closes gaps in the model